Plate & Frame Heat Exchangers

At HeatEX Technologies, we manufacture top-notch plate and frame heat exchangers, known for their exceptional performance, flexible design, and enhanced efficiency. Our products deliver reliable heat transfer solutions tailored to a wide array of applications.

What are Plate & Frame Heat Exchangers?

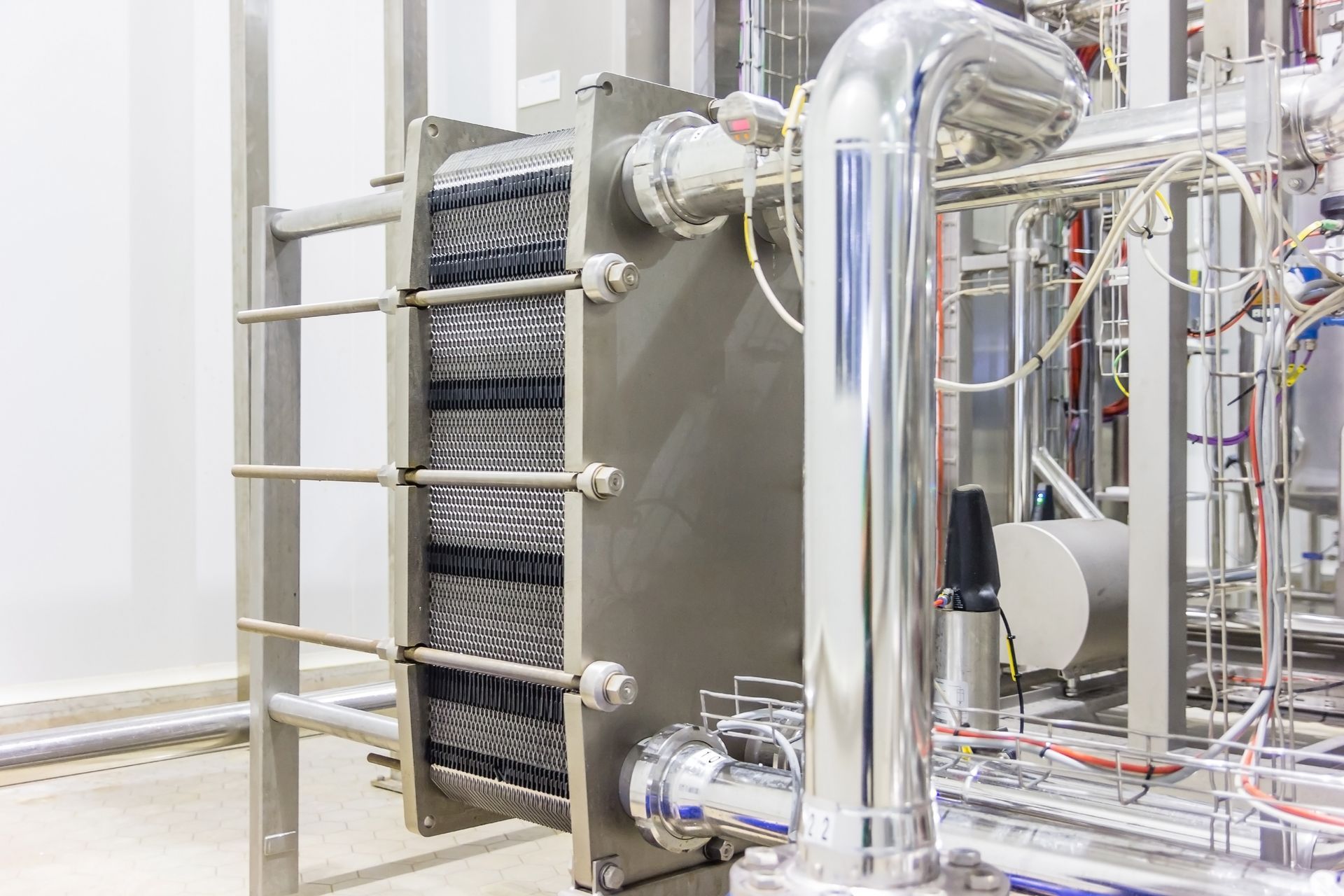

Plate and frame heat exchangers (PFHEs) consist of a series of thin, corrugated plates assembled in a frame. The plates form parallel flow channels, allowing two different fluids to flow separately through alternate channels without any direct mixing. The thin walls of the plates facilitate highly effective heat transfer from one fluid to the other.

Anatomy of a Plate & Frame Heat Exchanger

PFHEs are made up of several stacked heat transfer plates arranged in a steel frame. Each plate is typically constructed from stainless steel or titanium for their exceptional heat transfer capabilities and corrosion resistance. The plates are separated by gaskets, which seal the channels and guide the fluids into alternate channels. The entire assembly is held together by tightening bolts, which compress the plates and ensure a secure seal.

Optimal Design for Maximum Efficiency

Our PFHEs are engineered with a focus on maximizing heat transfer while minimizing energy usage. The corrugated pattern of the plates creates a turbulent flow, even at low flow rates, enhancing the heat transfer coefficient and preventing fouling. The modular design of the PFHE allows for easy expansion or modification as your system needs change over time. Furthermore, the use of durable materials ensures a long service life.

Applications of Plate & Frame Heat Exchangers

PFHEs are versatile and find use in various sectors:

- HVAC Systems: PFHEs are employed in HVAC systems for applications such as space heating, chilled water cooling, and domestic hot water supply.

- Industrial Processes: PFHEs are ideal for various industrial processes in the chemical, pharmaceutical, and food & beverage sectors where precise temperature control is critical.

- Power Generation: PFHEs play a crucial role in power plants by controlling the temperature of various processes, including lubrication oil cooling, generator cooling, and steam condensing.

- Marine Applications: In marine environments, PFHEs are often used for engine and oil cooling, fresh water generation, and central cooling systems.

- Waste Heat Recovery: PFHEs can be utilized to recover waste heat from various industrial processes, contributing to overall energy efficiency and sustainability.

Plate and frame heat exchangers offer a highly efficient and adaptable solution for a wide range of heating and cooling applications. They can be customized to meet specific requirements and system configurations. For more detailed information on how our PFHEs can be tailored to your needs, or for further insights into their operation, feel free to contact us. At HeatEX Technologies, our commitment is to deliver top-tier products that meet your needs and exceed your expectations in all aspects.

All Rights Reserved | HeatEX Technologies LLC